Perforated Metal Sheet

Leading Manufacturer of Perforated Metal Sheet, GI/SS/MS Perforated Sheet, Decorative Sheet, Metal Screens - Smarter Material For Industrial-Grade Solutions

Perforated metal sheets aren’t just flat pieces of steel with holes—they’re precision-engineered surfaces designed for airflow, filtration, weight reduction, and aesthetics. From acoustic panels in performance halls to anti-slip surfaces in industrial catwalks, they solve real-world engineering and architectural problems. Perforated Metal Sheets also called Punched or Perforated Plates.

What Are Perforated Metal Sheets?

Think of perforated metal sheets as metal panels with a custom pattern of holes—round, square, hexagonal, or even decorative shapes. These holes aren’t just for looks; they serve practical purposes like ventilation, sound control, or material separation. Made from materials like stainless steel, aluminum, carbon steel, or even exotic alloys, these sheets are built to handle tough environments while staying lightweight and visually appealing.

⚙️ Design & Material Specifications

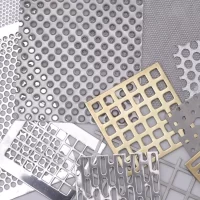

When we talk about perforated metal sheets, we’re looking at a customizable matrix of holes (or sometimes slots) punched through metal panels like:

Material Options:

Stainless Steel 304/316 (great for corrosion resistance and cleanrooms) , ideal for food processing or marine environments.

Galvanized Steel (cost-effective for outdoor or high-moisture applications)

Aluminum (lightweight, non-corrosive, and easy to form), rust-proof, perfect for outdoor signage or aerospace.

Copper & Brass (for architectural and artistic uses)

Carbon Steel: Budget-friendly, strong, often coated for durability in construction.

Specialty Metals: Copper for antimicrobial properties or titanium for extreme conditions.

Standard Thickness Range: 0.4 mm to 12 mm. though heavy-duty industrial sheets can hit 12mm. Thinner sheets (0.5–1.5mm) are popular for architectural cladding.

Sheet Size: Standard sizes are 4’x8’ or 5’x10’, but custom cuts are common. Maximum width often caps at 60” due to manufacturing limits.

Hole Sizes: As small as 0.5 mm to over 50 mm

Hole Patterns:

Round (most common for ventilation and filtration)

Square (for modern aesthetics and load-bearing grids)

Slotted/Oblong (ideal for drainage, screening)

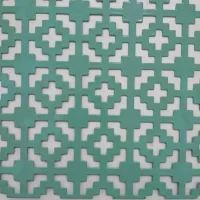

Decorative (used in facades and interior design)

Round holes dominate (60% of use cases), followed by square (20%) and slotted (15%). Custom patterns like cloverleaf or starburst are niche but growing in demand for decorative projects.

Open Area Percentage: This is the percentage of the sheet that’s “open” (i.e., holes). Can range from 10% to 70% depending on application—this directly affects airflow, light passage, and weight. Most common is 30–50% for balanced strength and function.

Punching Type: Conventional and CNC Type.

Features: Perfect Thickness, High Material Strength, Durable, Corrosion and Abrasion Resistant, Low Maintenance

Why Choose Perforated Metal Sheets?

1. Versatility in Applications

Architecture: Think modern building facades, sunshades, or interior partitions. Perforated aluminum sheets with 40% open area are hot for energy-efficient designs, cutting solar heat gain by up to 30%.

Industrial: Used in vibrating screens for mining or sieves in agriculture. Stainless steel sheets with 1mm round holes are standard for sorting grains or aggregates.

Acoustics: Perforated panels with 20–30% open area, paired with acoustic backing, reduce noise by 15–25 dB in auditoriums or factories.

Filtration: From HVAC systems to water treatment, sheets with precise hole sizes (0.5–5mm) filter particles while maintaining flow.

Safety: Anti-slip perforated sheets with raised hole edges are a go-to for walkways in oil refineries or warehouses.

2. Customization is King

Unlike solid metal sheets, perforated sheets are endlessly customizable. You can tweak:

Hole size (0.1mm to 50mm).

Hole spacing (staggered or straight rows).

Margins and unperforated borders for structural integrity.

Finishes like powder coating, anodizing, or galvanizing for extra durability or style.

3. Sustainability Edge

Perforated sheets are eco-friendly. Aluminum and stainless steel are 100% recyclable, and the perforation process minimizes material waste. Plus, their lightweight nature cuts shipping emissions—aluminum sheets weigh 30% less than solid counterparts.

🔧 Customization & Compatibility

One of the biggest reasons engineers and architects choose perforated sheets is flexibility. Customization isn’t a bonus—it’s standard.

Custom Hole Patterns: You can match brand aesthetics or acoustic behavior. Round holes dominate (60% of use cases), followed by square (20%) and slotted (15%). Custom patterns like cloverleaf or starburst are niche but growing in demand for decorative projects.

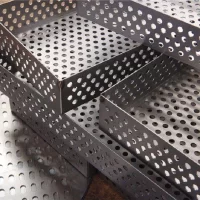

Forming and Bending: Sheets can be bent or rolled into shapes for curved walls, enclosures, or cylinders.

Powder Coating & Anodizing: Enhance corrosion resistance, color matching, or reflectivity.

CNC & Laser-Cut Precision: Tight tolerances are achievable, especially in high-precision applications like aerospace and electronics.

It also plays well with others—compatible with framing systems, structural supports, cladding fasteners, and ducting assemblies.

✅ Key Advantages (Beyond the Obvious)

While most people know about airflow and filtration benefits, the real-world perks go deeper:

🔊 Noise Control: Used with acoustic foam backing, it’s a go-to for sound-dampening enclosures and theaters.

💨 Thermal Ventilation: Ideal in heat-sensitive installations like HVAC units and generator housings.

🦺 Slip Resistance: Used for safe walking surfaces in factories, oil rigs, and loading docks.

🌱 Green Building Ready: Allows daylight penetration while reducing HVAC loads—used in LEED-certified facades.

- Micro-Perforation: Tiny holes (0.1–0.5mm) are trending in electronics for heat dissipation and speaker grilles.

- Aesthetic Appeal: Decorative perforations (like geometric or floral patterns) are hot in retail and hospitality, with 30% more inquiries for custom designs in last few years.

🏭 Industry Applications

Search trends show that most queries around perforated sheets are tied to very specific use cases. Here are the big players:

Architecture & Facades: Used for sunscreens, balcony rails, ceilings, and decorative partitions.

Agriculture: Grain dryers, seed sorters, and ventilation panels in silos.

Food Processing: Stainless options used for sieves, fry baskets, and hygiene-friendly flooring.

Industrial Filtration: Oil filtration, mining screens, centrifuge drums.

Transportation: Train platform panels, bus grilles, sound barriers along highways.

🧽 Maintenance Tips That Actually Matter

For aluminum or coated steel, rinse with water and mild detergent monthly in dusty environments.

In coastal or chemical-exposed environments, inspect stainless steel every 6–12 months for pitting or rust blooms—early action prevents expensive replacements.

Avoid abrasive brushes on coated surfaces—micro-scratches can compromise protective layers.

Use a compressed air blower for dry, indoor installations (especially ceilings) to prevent buildup without damaging coatings.

Technical Considerations for Your Project

When picking perforated metal sheets, here’s what to keep in mind to avoid hassle:

Strength vs. Open Area

More holes mean less material, which can reduce tensile strength. For structural applications like railings, stick to 20–30% open area and thicker gauges (2–4mm). For decorative panels, you can push to 50% open area with thinner sheets (1mm).

Hole Size and Flow

For filtration or ventilation, hole size matters. Smaller holes (0.5–2mm) are great for fine particle separation but may clog faster. Larger holes (5–10mm) maximize airflow but sacrifice precision. Calculate your required flow rate (CFM or LPM) and consult a perforation chart to match.

Corrosion Resistance

Outdoor or humid environments demand corrosion-resistant materials. Stainless steel 316 outperforms 304 in salty coastal areas, lasting 20% longer. Aluminum with anodized finishes resists UV and weathering better than untreated carbon steel.

Fabrication Tips

Cutting: Laser or waterjet cutting preserves hole integrity better than shearing.

Forming: Perforated sheets can be bent or rolled, but tight radii may distort holes near edges.

Welding: Use TIG welding for stainless steel to avoid burn-through around holes.

Engineerswiremesh is a leading manufacturer and exporter of Stainless Steel 304 Perforated Sheet, MS Perforated Sheet, Aluminum Perforated Sheet, Perforated Sheet Mesh and GI Perforated Sheet. These products are manufactured by our professional team using high grade raw materials. These products are known for their strength and durability. Quality is the precedence of our firm. These products are demanded in different industries for various purposes like filtration, decorative uses and much more. We have set of tools to perforate different holes sizes with different pattern. We provide customization as per the specifications laid down by the customers. We are exporting our products globally.

The quality of our products is checked by our qualified quality control professionals before delivery. Our supply chain system is capable of enabling timely delivery within affordable budget. Best quality at best price is our priority.